A recent example of ESILV’s commitment to research excellence is the publication of the paper Local Layer Splitting: An Additive Manufacturing Method to Define the Mechanical Properties of Soft Pneumatic Actuators During Fabrication by ESILV graduate student Thibault Charlet (Class of 2022) and Marc Teyssier, Professor-Researcher at the Institute for Future Technologies (IFT).

This work was presented at the 2023 IEEE International Conference on Robotics and Automation (ICRA), one of the most prestigious events in the robotics field.

Innovating Soft Pneumatic Actuators: A New Approach to Additive Manufacturing with Local Layer Splitting

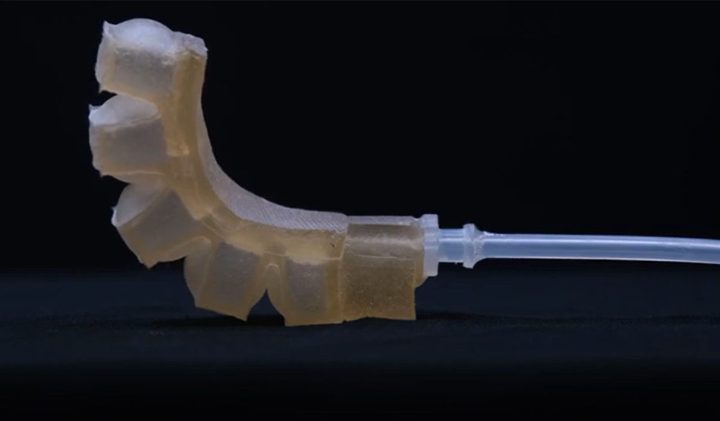

The research explores the additive manufacturing of silicone as a complement to traditional molding techniques for Soft Pneumatic Actuators (SPAs).

SPAs’ mechanical behavior is typically dictated by their 3D form, often requiring trade-offs between mechanical properties and structural aesthetics.

This study introduces a novel fabrication method, Local Layer Splitting (LLS), where mechanical properties are defined during the manufacturing phase rather than the 3D modeling stage.

Key Findings and Impact

The LLS method enables controlled mechanical deformation by integrating variations in stiffness through localized modifications of the printing layer height.

The research demonstrates that layer height parameters influence the final stiffness of the silicone material, allowing for programmed bending deformations directly during printing. Key findings include:

- Characterization of the impact of printing layer height on silicone stiffness through tensile testing.

- Development of a custom slicer to generate G-code instructions that vary layer heights based on x and y positions.

- Validation that SPAs fabricated using LLS achieve bending and force characteristics comparable to state-of-the-art SPAs.

- A paradigm shift in SPA design, transferring bending behavior integration from the 3D modeling phase to the fabrication process.

This research exemplifies how ESILV’s Research Pathway fosters student-led innovation with real-world applications. Its publication at ICRA validates the work’s scientific contribution and underscores ESILV’s role in advancing additive manufacturing technologies.

The International Conference on Robotics and Automation

As an internationally recognized platform for advancing robotics, ICRA provides a valuable stage for showcasing breakthrough research.

The IEEE International Conference on Robotics and Automation (ICRA) is an annual academic conference highlighting the latest robotics advancements.

Recognized as one of the premier conferences in the field, alongside the International Conference on Intelligent Robots and Systems (IROS), ICRA has received top academic rankings, including an ‘A’ rating from the Australian Ranking of ICT Conferences in 2010 and an ‘A1’ rating from the Brazilian Ministry of Education in 2012.

ESILV Research Pathway: Bridging Academia and Industry through Cutting-Edge Innovation

The Research Pathway at ESILV prepares students for academic research doctoral studies and careers in Research and development (R&D) departments of major companies and innovative startups.

During their fourth and/or fifth year, student researchers engage in a research project under the supervision of De Vinci Research Center faculty members. Embedded within a research team, they develop essential research competencies, including R&D project management, constructing scientific literature reviews, conducting experimental studies, and mastering scientific communication.

This program stands as a unique feature of ESILV, providing students with the opportunity to contribute to cutting-edge research while gaining recognition through publications in esteemed scientific conferences and journals. Highlighting student achievements and research outcomes through official ESILV channels complements individual valorization efforts and reinforces the program’s impact.

By emphasizing research outcomes and student publications, ESILV continues reinforcing its position as a hub for engineering innovation and knowledge creation, bridging the gap between academic research and industrial applications.