Mathis and Yohann, class of 2024, are in their fourth year at ESILV, specialising in the Creative Technology major. They opted for this major within the Devinci Innovation Center (DVIC), because they are attracted by the creation of projects that allow them to develop their technology skills.

Being fans and practitioners of extreme sports and boarding, specifically downhill longboarding (a sport that consists of taking skateboards and going downhill at high speed on the road), Mathis and Yohann noticed that the boards used in this sport are often made with unsustainable and polluting materials. Creating an eco-friendly board was the challenge they set themselves.

Students get into SK8

All materials used to reinforce the boards contain fibers. These fibers are placed on top and underneath the boards to strengthen and give them good mechanical properties. Unfortunately, these fibers are usually made from polluting materials such as carbon or artificial glass.

Mathis Tiberghien and Yohann Cossez are studying together in the Creative Technology major at DVIC, which trains students to become Creative Technologists. This profession consists of creating new products or new uses by using advanced technologies and scientific knowledge.

They decided to test the viability of using natural fibers in manufacturing skateboards to replace polluting fibers and reduce their environmental impact. They wanted to see if these new boards could achieve mechanical properties as good as traditional boards.

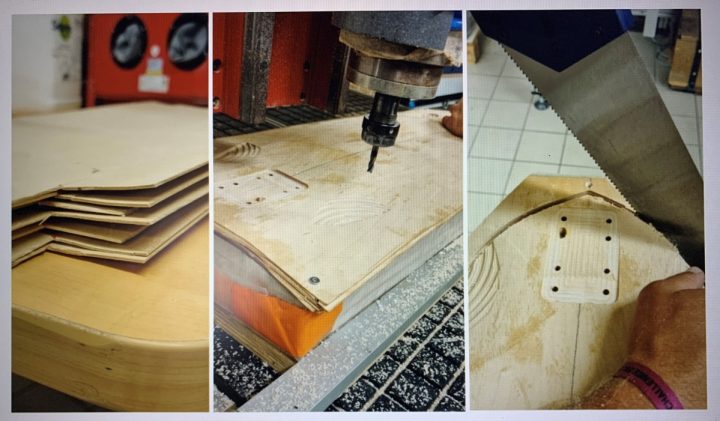

They started by making the first board using artificial fibers to learn the necessary manufacturing techniques and test all the steps in making a skateboard. Then they made two new boards using natural, low-emission fibers. They then put wheels on these boards, tested them, and found that they worked properly.

We have carried out product tests, and today we can say it is possible!

The manufacture of natural fibre skateboards at DVIC

What about the quality of the skateboards?

After testing, Mathis and Yohann discovered that using natural fibers has disadvantages. As the boards require glue for their manufacture, it is possible that more glue is needed by using natural fibers, which may reduce the durability of the final product.

However, they have made much more durable boards with interesting mechanical properties, offering a slightly different feel.

As riders, we have also opened up possibilities for new sensations in board sports.

When Mathis and Yohann tested their durable board, they found it flexible. They made downhill boards, which reached very high speeds on the road. The last two boards they made using natural fibers are freestyle boards.

These boards are used for tricks. They have specific characteristics, such as the “pop,” which allows you to more or less take off from the ground while doing jumps.

New materials for new sensations

As in all sports, the sensations are significant. In skateboarding, the user experiences different feelings depending on the materials used to make the board. The boards can be approximately flexible, with varying elasticity curves, which gives other sensations depending on the materials used.

Since they used new materials that had been very little used before, they discovered new sensations that they had yet to experience with traditional boards.

Testing the viability of new materials in board sports, in general, seemed like a no-brainer, as the two engineering students feel that skateboarding is the sport they excel in the most.

In terms of feel, it’s a minimal feel, but still using these materials, we found it extremely interesting and think it could be a big step forward..

Skateboard manufacturers share the same manufacturing techniques and construction as skis, snowboards, or other boards such as kiteboards and wakeboards.

Mathis and Yohann believe that if they can make skates from natural fibers, they could also make skis or snowboards.

The influence of the DVIC in this project

It is the DVIC, within the Learning Center, in which Mathis and Yohann evolved to do their project and which gave them all the keys in hand to succeed in this project.

When an idea is creative and deserves to be developed, the DVIC gives us all the necessary advice and funds and accompanies us in this project. Thanks to the school and mainly to the DVIC and the whole institute around it, we can develop projects like this.

The Future of sustainable skateboards

Mathis and Yohann identified the limits of their project by carrying out life cycle analyses (LCAs). LCAs are tools that allow the environmental impact of a product to be analysed on several criteria. As they explain, the manufacture of a product may be environmentally friendly, but, likely, the materials and components upstream are not at all.

We analyse the whole life cycle of a product, from the extraction of the raw materials to the end of life, in other words, the product’s recyclability. We could do something eco-responsible, for example, in China, but then we have to send them to Europe, so there is a significant carbon footprint at that point. In the case of our skateboards, we could not do the LCAs to check precisely how eco-friendly the product is. This was the limit of our project..

Nevertheless, the two students would like to go further and become more professional.

For the moment, we are in the exploration phase. There is so much to develop in this fiber.

Natural fibre skateboards

Carbon fiber is a material that has been extensively developed and studied to try to make it ultra-strong. As a result, it is a solid fiber with unique mechanical properties today.

It is possible to create reinforced materials from natural fibers such as basalt and flax fiber, as was done for Mathis and Yohann’s skates. Research could be undertaken to develop these materials and make them as strong as carbon, but with a much lower environmental impact.

Flax fiber, for example, is cheaper than carbon. Economically, it is viable, and in terms of sustainability, it is excellent!

Going after their dreams, skateboarding or not

For his part, Mathis wants to continue his involvement in the work and research of natural fibers. He now has unique knowledge in this field and wants to apply it in other areas, such as building structures for cars.

As for Yohann, he has always been passionate about design and mechanics, and he wants to stay in the field of eco-design. For him, being able to combine these two fields while reducing the carbon impact as much as possible is a significant challenge.

Both have ambitions and dreams that go back to their childhood, as they explained in their testimonies.

About 15 years ago, when I started extreme sports, I didn’t think I could bring this into my work. For me, board sports were a hobby that I would have to stop sooner or later or at least reduce in favour of my studies. Being able to carry out this kind of project, mainly thanks to the Devinci Innovation Center, is a golden opportunity for me, and I intend to make the most of it! Little Yohann would be proud to see Big Yohann doing a project so close to his heart.

I went to ESILV precisely to design, invent things, to use and test new materials. That’s what I’ve wanted to do since I was a child. At DVIC, they allowed me to do what I wanted to do when I was little. To little Mathis: go on, go to this school, and then you will see that at the end, they will give you all the cards in hand to do what you want to do!

With their project, Mathis and Yohann try to give people ideas and show them that everything is possible, even to develop more sustainably and cheaper.

Learn more about the major in Creative Technology