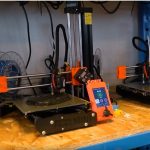

3D Printing is crucial for various fields of activity such as industry and healthcare and is now commonplace. Additive manufacturing is also a vast terrain of experimentation for the De Vinci Innovation Center, the cross-disciplinary innovation cluster of the Pôle Léonard de Vinci.

In an article published in The Conversation France, Clément Duhart, head of the De Vinci Innovation Center – DVIC, gives his take on the latest challenges and developments in 3D Printing.

Smart materials

At the De Vinci Innovation Center, we explore two main areas of life-inspired additive manufacturing: smart materials and organic materials.

Printed objects made of plastic, resin, but also, here, of silicon doped with a metallic powder to make an intelligent flexible sensor

The engineering mindset tends to separate a system into sub-assemblies, the electronics on one side and the mechanical body on the other. This division of labour is present at all stages of product design, from design to industrialisation.

This way of thinking contrasts with nature’s approach, which is very ‘integrated’ as we would say in engineering jargon. Its decision systems, sensory sensors and muscle actuators are all part of a whole. As a result, this type of design offers many robustness, aesthetics, and integration advantages.

The exploration of intelligent materials consists of creating matters in which all the elements are directly integrated. Thanks to additive manufacturing, an object can be designed with different materials with different mechanical properties while at the same time incorporating electronic circuits made of conductive ink, for example.

It is also possible to consider new types of energy for motorisation, such as pneumatic or hydraulic pressure, by designing more or less complex channel structures within the fabric during printing.

For example, we have experimented with designing pneumatic muscles that we can combine with conductive ink to develop stretch sensors inspired by work in soft robotics. It is then impossible to separate the actuator from the sensor, and both become a single substance.

For instance, we have created a multilayered synthetic skin incorporating the dermis, epidermis, veins and a texture capable of feeling the touch. To continue this work, we have set up a research chair with the start-up Lynxter to explore the opportunities of so-called smart materials in additive manufacturing. One day, the hope is that a biological 3D printer may be born, with the ability to print organs or live autonomous structures as depicted in the film ‘The Fifth Element’.

Materials derived from the living world

In recent years, cheap raw materials have influenced industrial and economic development and the drive towards accessible energy, primarily extracted from oil. However, their abundance has prevented us from thinking about matter in any other way than through steel and plastics.

We are now beginning to rethink our relationship to manufactured objects and technological tools, notably through the so-called “low tech” movements. The design of new products is influenced by new materials and mechanisms drawn from the living world and inspired by our planet’s biodiversity.

For example, thick silk is a solid and flexible fabric with low production costs and potentially local and is biodegradable when exposed to ultraviolet light. Therefore, we could consider making a chair back that is customised to our back by additive manufacturing in silk and with low ecological impact in terms of raw material production and grey energy, rather than a high carbon impact plastic chair.

Two students develop a lichen-based micro-porous material for use in clothing

Some of the ‘Resilient Futures’ group led by Marc Teyssier focuses on the cultivation of living cells for the production and packaging of organic material for additive manufacturing, in collaboration with the French start-up MASP. One of the short-term objectives is to process silk on a massive scale, but other organic materials are also being considered.

For example, once processed, coffee grounds can be printed and then stabilised to create animal leather-like coatings – an activity inspired by the fab lab in Barcelona. In food manufacturing, we explore how molecular cooking and fusion can be used to print food in three dimensions.

Can 3D printing drive the green revolution in industry and logistics?

Plastic and resin additive manufacturing has often been associated with a high carbon footprint due to the raw material. Many projects and companies are trying to recycle this raw material into new printing threads, but these attempts are limited so far. On the one hand, the quality of the recycled material is not always satisfactory for finished products. On the other hand, the reprocessing processes impact the planet, even though research activities tend to improve this status quo.

Today, waste from plastic or resin additive manufacturing can flow through the traditional recovery chain and be used in other industrial sectors that are less demanding in terms of chemical and mechanical properties, e.g. for construction materials.

Finally, the cultivation of living materials allows us to think beyond oil and see new technologies as an opportunity for change. For example, suppose additive manufacturing is already a formidable prototyping tool. In that case, it is now becoming a full-material manufacturing tool – potentially greener – and a custom manufacturing tool – thus adapted to usages.

As Neil Gershenfeld, the inventor of fab labs has pointed out, it can even reduce the transport of goods. Finished products would no longer need to travel several times worldwide, given the distances travelled by the various parts that make up the product.