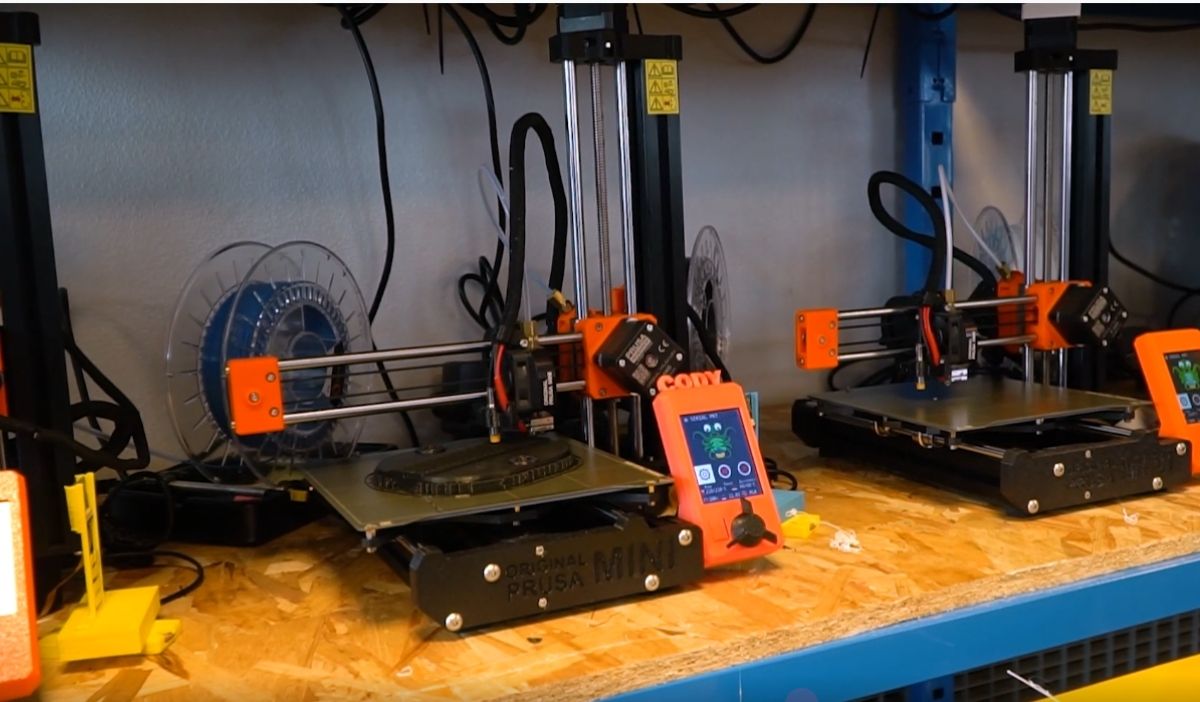

3D printing, the process of producing 3-dimensional objects from a computer file, presents many advantages when it comes to manufacturing, which offers a multitude of possibilities, sometimes unexpected…

ESILV School of Engineering has its own FabLab equipped with 3D Printers for students to experiment with this revolutionary technology. The Industry 4.0 Major trains them to use tools of the digital revolution, including 3D Printers.

Corals

We all know it: coral reefs are in peril. With climate change, pollution of the oceans and intensive fishing, their presence is alarmingly decreasing.

To fight this process, researchers from Cambridge University and the University of California San Diego have decided to recreate corals from with the help of a 3D Printer. They used a combination of polymer gels and hydrogels doped with cellulose nanomaterials to mimic the optical properties of living corals.

A Bikini

Printing its bath suit from home? Continuum fashion made it! The brand describes this revolutionary piece of clothing as ‘the world’s first ready-to-wear, 3D printed article of clothing’.

The N12 bikini is named after the material it is made out: nylon 12. All of its pieces are made directly by 3D printing and don’t need any sewing skills to be assembled.

The N12 bikini cost 150 euros, and while it couldn’t be described as particularly groundbreaking in terms of style, it is indeed an interesting piece of clothing to brag about on the beach.

A Bionic Ear

Scientists from Princeton University have managed to merge electronics and biology to create an ear that can actually hear radio frequencies. This bionic ear, whose antenna and tissue were made from a 3D printer, has the potential to not only restore hearing but also enhance it.

The researchers have commented that “Cybernetics field has the potential to generate customized replacement parts for the human body, or even create organs containing capabilities beyond what human biology ordinarily provides.”Cybernetics does not exist only in sci-fi movies anymore!

A Pizza

Originally initiated by NASA back in 2013 to give astronauts access to a larger variety of food, the 3D printed pizza will probably soon become accessible to all thanks to BeeHex’s 3D printers.

This technology has already been showcased in theme parks and malls, and present the advantage of allowing the client to personalise its pizza without increasing the price. Clients won’t even have to possess a 3D printer, their order will be sent via an app to the 3D Printer pizzaïolo.

3D Printers are still in their early stage of development. With such a huge potential, there is no doubt that this technology at the core of Industry 4.0 will revolutionise manufacturing in the next few years.

Interested in Engineering? Check out ESILV’s programmes.

This post was last modified on 5 November 2020 12:40 pm